Challenges Created Due To Over-Rolling A Tube

To ensure high-quality tube expansions, the tube wall must be reduced by a predetermined percentage. A mechanical tube joint is formed when the outer diameter of the tube is compressed against a fixed container. Ideally, rolled joints are created when the tube state turns to plastic (stays where it stops) and is contained by the tube sheet’s elastic properties (fully recovers). Rolling to the proper wall reduction will decrease the chances of under-rolling and over-rolling a tube, creating higher quality mechanical joints.

Tubes are considered over-rolled when the expansion of the tube surpasses the expansion required for the proper wall reduction. Over-rolling can decrease the distance and strength of the ligaments between tubes, causing considerable damage to the tube sheet and tubes. Once a ligament is weakened, it will reduce the strength of those surrounding it. This overall reduction in ligament strength can cause adjacent tubes to leak. Distortion to the tube sheet or drum can also be created due to over-rolling.

In addition to altering the tubes in a vessel, over-rolling can have a significant impact on expander tool life. Over-rolling can cause the tube material to flake off, which can get trapped between the rolls and mandrel. If this debris is not cleaned from the expander, it can reduce the life of the rolls and mandrels. In cases where over-rolling exceeds the upper expansion limit of the tool, the cavities of the cage can become damaged, resulting in the inability of the cavity to retain the roll. In this case, the cage would then need to be replaced. As a result, over-rolling will lead to a reduction in tool life of the rolls and mandrels.

When a tube is over-rolled, there isn’t a lot that can be done to correct the issue. Once the tube sheet ligaments are weakened, the entire heat exchanger or boiler will be more likely to experience leaks and decreases in efficiency. This results in additional rework and maintenance costs for the company.

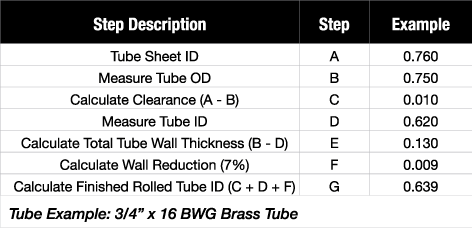

In order to avoid over-rolling, it is important to get an accurate tube OD and ID measurement prior to expansion. These measurements can help you determine what the rolled ID should be at the proper wall reduction (see table below).

Additionally, an electronic torque control should be used to control the amount of expansion that takes place. This can help reduce operator error while rolling.

For assistance with properly calculating the Roll ID, Elliott offers several resources on our website, including Basic Principles of Tube Expanding and an Expansion Calculation Tool.