Minimum vs Average Wall Tubes & Why It Matters

Getting the right tools for your application is critical in order to complete the job right the first time. One of the most overlooked factors when ordering tooling, is determining whether you have minimum wall or average wall tubing.

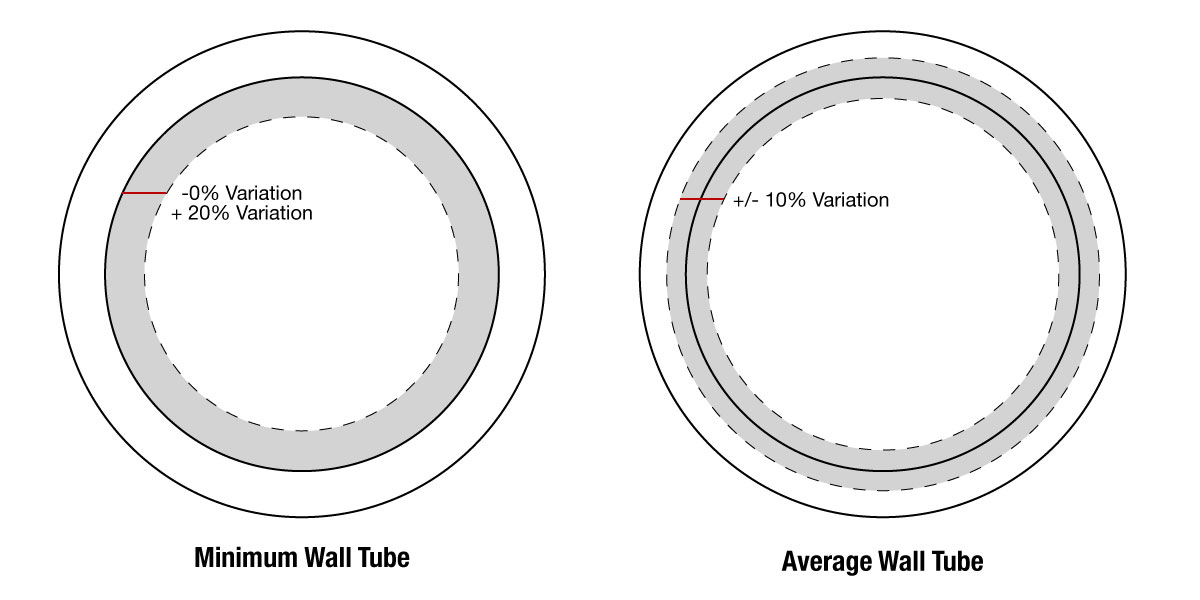

When ordering tubes, it is very unlikely that each wall thickness will be exactly the same. Industry tolerances allow for ±10% thickness. That’s a total variation of up to 20% from the smallest to largest thickness, resulting in a wide range of sizes. For example, if you have .083” average wall tubes, the actual wall could be anywhere between .091” and .075”. If you were to buy a 14 BWG expander to fit .083, it would likely still work for either extreme due to the expansion range that the tool is capable of achieving.

However, many times a heat exchanger manufacturer needs to achieve a very specific thermal transfer. In order to achieve this, they need to guarantee that the wall thickness of the tubes will be a minimum thickness. So for many applications, the manufacturer will request minimum wall (min wall) tubes.

A min wall tube offers the same total variation in wall thickness that an average wall tube does, but the variation is applied differently. It allows for -0% and +20%. So the wall will never be less than the specified thickness. For example, a .083” min wall tube will range from .083” to .100” wall thickness.

At the upper end of that range, a normally sized tube expander will not have enough clearance to enter the tube. If you have min wall tubing, it is recommended that you drop down one expander size. So instead of ordering a 14 BWG expander, you would drop down to a 13 BWG. This ensures that the expander will fit inside of the tubes and still achieve the proper range of expansion.

If you are unsure whether or not you have min wall or average wall tubing, it is important that you measure the inside diameter (ID) of your tubes prior to ordering tooling. If you do not take an average measurement, you may end up having to order additional sizes or spend time re-rolling tube joints later on. Taking ID measurements are always recommended, even if you know what type of tubing you have. The more precision measurement you have, the more accurate you can be when

ordering your tooling.

Overall, it is important to understand the difference between average and min wall tubing, and to know the type you are working with in order to achieve the best results.